From Bagru to the World: The Global Eco-Revolution of Hand-Block Printing

2/7/2026

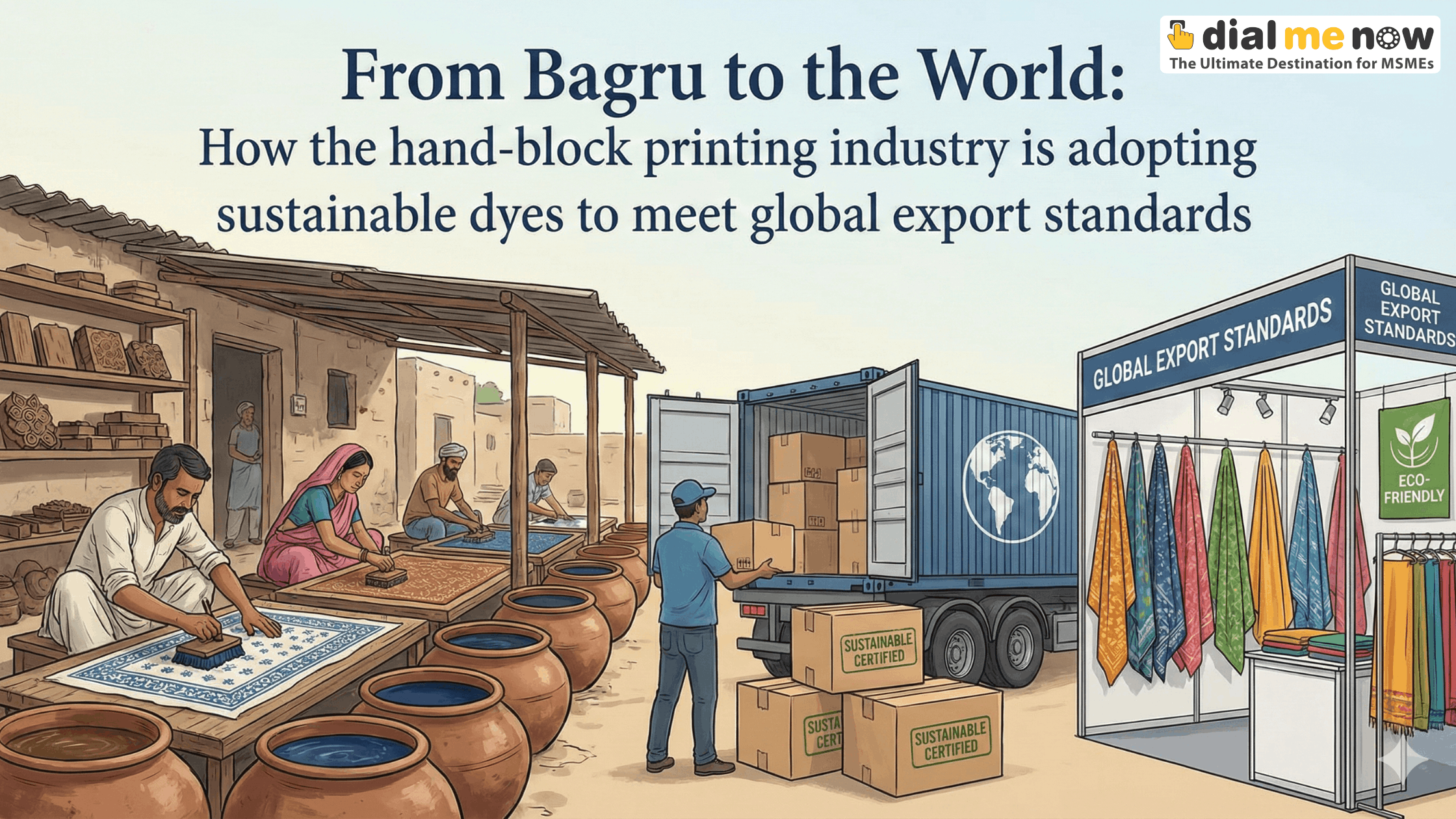

In the dusty lanes of Bagru, a small town just 30 kilometers from Jaipur, a rhythmic thap-thap sound echoes through the air. This is the sound of history being carved, stamped, and preserved. But in 2026, this ancient craft is doing more than just staying alive; it is leading a global fashion revolution.

As international markets—particularly the EU and North America—tighten their environmental regulations with initiatives like the Ecodesign for Sustainable Products Regulation (ESPR), Bagru’s traditional hand-block printing is emerging as a gold standard for ethical production. By marrying 400-year-old techniques with modern sustainable dye standards, the “Chippa” community of Bagru is proving that the future of fashion is hidden in its past.

The Alchemist’s Palette: Nature’s Sustainable Dyes

Unlike mass-produced textiles that rely on heavy-metal-laden synthetic colors, Bagru’s signature lies in its “living” colors. The transition to meeting Global Organic Textile Standards (GOTS) and AZO-free certifications has seen a resurgence in traditional plant and mineral-based recipes.

- Indigo (The King of Dyes): Derived from the Indigofera tinctoria plant, this deep blue is achieved through natural fermentation in vats. It requires no electricity and the water can often be reused for irrigation.

- Fermented Iron (The Bagru Black): Rusted iron scraps (often old horseshoes) are fermented with jaggery (raw sugar) for 15 days to create a rich, permanent black dye called Syahi.

- Madder Root & Alizarin (The Royal Red): The roots of the madder plant are used to achieve shades ranging from soft pink to deep crimson, fixed with natural alum.

- Pomegranate Rind (The Earthy Yellow): Dried rinds of pomegranate (Nasphal) are boiled to create vibrant yellows and greens, doubling as a natural moth repellent for the fabric.

Dabu: The Mud-Resist Magic

Bagru is world-renowned for Dabu, a unique mud-resist printing technique that is inherently eco-friendly.

- The Paste: Artisans create a thick paste using local black clay, Beedan (wheat chaff), lime, and Gond (natural gum).

- The Resist: This “mud” is stamped onto the fabric using wooden blocks. Sawdust is then sprinkled over the wet mud to prevent smudging.

- The Dyeing: When the fabric is dipped into the indigo vat, the mud prevents the dye from penetrating those areas.

- The Reveal: Once washed, the mud falls away, revealing a beautiful, crisp white pattern against a sea of blue.

Meeting Global Standards in 2026

The Indian government’s 2026 Tex-Eco Initiative and the National Handloom and Handicraft Programme have provided Bagru’s artisans with the tools to compete on a global scale.

- ZLD (Zero Liquid Discharge): Modernized clusters in Bagru are adopting communal water filtration systems that ensure that even the minimal wastewater from natural dyeing is treated and recycled.

- Digital Product Passports: To meet EU requirements, many Bagru exporters now use QR codes on garment tags. These “passports” track the fabric’s journey from the cotton farm to the specific artisan family in Bagru, proving its ethical and chemical-free origin.

- Traceable Fibers: There is a heavy shift toward printing on GOTS-certified organic cotton, silk-linen blends, and even hemp, ensuring the entire garment meets international “Green Deal” standards.

Comparison: Bagru vs. Synthetic Fast Fashion

| Feature | Bagru Hand-Block Printing | Synthetic Screen Printing |

| Dye Source | Plants, Minerals, Fermented Iron | Petroleum-based Chemicals |

| Energy Use | Manual stamping, Sun-drying | Heavy Industrial Machinery |

| Water Impact | Biodegradable runoff | Toxic chemical discharge |

| Skin Safety | Hypoallergenic & Breathable | Can cause dermatitis/sensitivities |

| Durability | Colors age gracefully (Vintage look) | Colors crack and flake over time |

Why Global Designers are Flocking to Bagru

In the age of “Slow Fashion,” Bagru offers something machines cannot: Soul.

- The Beauty of Imperfection: No two meters of Bagru fabric are identical. The slight variations in the “smack” of the block or the depth of the dye vat are seen by luxury brands as a mark of authenticity.

- Low Carbon Footprint: Because the process relies on the sun for drying and manual labor for printing, it is one of the lowest-carbon textile methods available today.

- Empowering Communities: Every purchase supports the Chippa community, ensuring that this Geographical Indication (GI) tagged craft isn’t lost to urbanization.

❓ Frequently Asked Questions (FAQ)

Q1: Do natural dyes in Bagru prints bleed or fade easily?

A: Natural dyes like Indigo and Madder are surprisingly colorfast when treated with traditional mordants like Harda (myrobalan). However, they do “breathe” and may fade slightly over years, taking on a soft, vintage character that is highly prized.

Q2: Is Bagru printing the same as Sanganeri printing?

A: No. While both are from Jaipur, Sanganeri usually features floral motifs on a white background using direct printing. Bagru is famous for its earthy tones (reds, blacks, blues) and the mud-resist Dabu technique.

Q3: How can I tell if a print is authentically hand-blocked?

A: Look at the edges of the motifs. In hand-block printing, you will see tiny overlaps or gaps where the blocks were joined. These “flaws” are the signature of the human hand.

Q4: Are the dyes safe for people with sensitive skin?

A: Yes! Since they are made from plants like turmeric and indigo, they are generally much safer and more breathable than synthetic azo-dyes.

Q5: Why is Bagru fabric more expensive than screen-printed fabric?

A: A single piece of Bagru fabric can take 4 to 14 days to produce, involving multiple stages of washing, printing, and sun-drying, all done by skilled artisans.

Q6: Can Bagru prints be done on silk?

A: Traditionally done on cotton, artisans now successfully apply these techniques to silk, Chanderi, and linen to cater to the luxury export market.

Q7: What is the “Harda” treatment?

A: Harda (Myrobalan) is a dried fruit used as a natural mordant. It gives the raw fabric a yellowish tint and is essential for the natural dyes to bind permanently to the fibers.

Q8: Is the Bagru industry protected?

A: Yes, Bagru Hand Block Printing has Geographical Indication (GI) status, which means only textiles produced in this specific region using traditional methods can legally use the name.

Disclaimer

The Bagru printing process is heavily dependent on weather conditions (especially sunlight). Production may slow down during the monsoon season. While we strive to connect you with the best artisans, the “imperfections” in the print are a characteristic of the handmade process and not a defect. Ensure you book through our official platform to support verified local cooperatives.

Conclusion

From the riverbeds of Rajasthan to the runways of Milan, Bagru’s hand-block printing has completed its journey. It is a testament to the fact that sustainability isn’t just a 2026 buzzword—it is a 400-year-old way of life. By choosing Bagru, you aren’t just wearing a pattern; you are wearing a piece of the earth.